At High Quality Plumbing Services, we specialize in professional gas line installation and repair, ensuring the safety and efficiency of your home or business's gas systems. Our team of licensed and experienced plumbers is dedicated to providing high-quality service tailored to meet your specific needs. Whether you are looking to install new gas lines for appliances, maintain existing systems, or address any repairs, we utilize state-of-the-art tools and techniques to guarantee precise work and compliance with all local codes and regulations. With a commitment to customer satisfaction, we prioritize safety and reliability, giving you peace of mind that your gas line needs are in expert hands.

The Gas Line Installation Process

Installing a gas line requires careful planning and adherence to safety protocols. The process typically begins with assessing the area where the line will be installed, ensuring compliance with local codes and regulations. A professional plumber will evaluate the existing infrastructure to determine the most suitable route for the line. Accurate measurements and assessments help in selecting the correct materials, which may include piping, connectors, and valves.

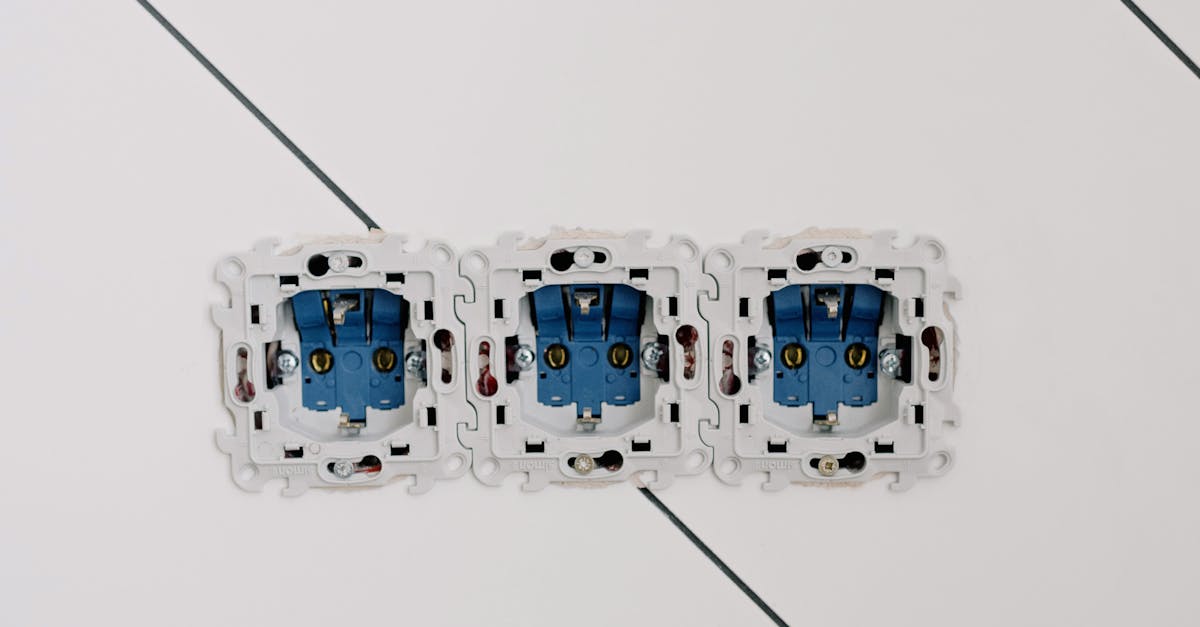

Once the planning stage is complete, the actual installation can begin. Trenches may need to be dug for underground pipes, and proper supports are essential for above-ground installations. Each connection must be secure and leak-tested before the line becomes operational. Following installation, the final step involves coordinating with local utility providers to ensure the gas supply is safely connected and functional.

StepbyStep Guide to Installation

The initial stage of gas line installation involves careful planning and assessment of the property. A qualified technician should conduct a thorough evaluation to determine the optimal route for the gas lines, considering factors such as accessibility, potential obstacles, and local building codes. After creating a detailed plan, the technician will gather all necessary materials and tools, which typically include pipes, fittings, valves, and a pressure gauge. Safety precautions must be emphasized throughout the process to prevent any hazards.

Once the materials are ready, the installation can begin. The technician will start by digging trenches if needed, ensuring the gas lines are buried at a depth compliant with regulations. After laying the pipes, connections are made using appropriate fittings, with all joints securely bonded to prevent leaks. Following the installation, tests are conducted to check for leaks and ensure proper pressure levels. This final step is crucial to guarantee that the gas line functions safely and efficiently before it is put into service.

Types of Gas Used in Residential Properties

Residential properties typically utilize either natural gas or propane as their primary fuel source. Natural gas is more commonly found in urban areas where pipelines are easily accessible. It is delivered through underground pipes directly to homes, providing a consistent and often more economical energy source for heating, cooking, and other appliances.

Propane, while less common in urban settings, is frequently used in rural areas where natural gas lines are not available. This fuel is stored in tanks and can be delivered on an as-needed basis. Propane furnaces and appliances offer versatility and efficiency, making them a viable alternative for homeowners who do not have access to natural gas. Each type of gas has its unique benefits, and understanding these differences helps in selecting the right option for residential needs.

Natural Gas vs. Propane

Natural gas and propane are both commonly used fuels for residential heating, cooking, and other energy needs. Natural gas is delivered via pipelines and is typically less expensive due to its abundant supply. It burns cleanly, producing fewer emissions compared to other fossil fuels, making it a popular choice for eco-conscious homeowners. On the other hand, propane is usually supplied in tanks and is more commonly found in rural areas where natural gas infrastructure is not available. While propane tends to have a higher cost, it offers flexibility and can be used in a variety of applications beyond heating, including barbecues and outdoor heaters.

Choosing between the two fuels often comes down to availability and specific household needs. Natural gas offers a consistent supply, which is beneficial for homes requiring continuous energy, while propane can be stored and used as needed. In terms of energy efficiency, both fuels perform well, though propane has a higher energy content by volume, which means it can heat spaces more quickly in some situations. Ultimately, the decision may also depend on regional factors and personal preferences regarding fuel type, supply reliability, and overall environmental impact.

Maintenance Tips for Your Gas Lines

Keeping your gas lines in good condition is crucial for safety and efficiency. Schedule regular checks to inspect for any signs of wear or leaks. A qualified technician can help identify potential issues that might go unnoticed. It’s essential to pay attention to the odor of gas, which is often described as a sulfur-like smell, as this can indicate a leak. Proper ventilation can also play a role in maintaining safe gas line functionality.

In addition to professional inspections, homeowners can perform simple routine checks. Look for rust, corrosion, or any visible damage along the gas line. Inspect the fittings and connections for signs of wear as well. Keeping the area around the gas lines clear of debris ensures easy access during inspections. Staying proactive about maintenance can not only enhance safety but also prolong the lifespan of your gas lines.

Regular Checks and Inspections

Ensuring the safety and efficiency of your gas lines requires regular checks and inspections as part of ongoing maintenance. Homeowners should familiarize themselves with signs of gas leaks such as unusual odors, hissing sounds, or dead grass patches around the line. Scheduling professional inspections every one to three years can help detect issues early. Inspectors will look for signs of corrosion, leaks, and proper connections, ensuring compliance with local codes.

Homeowners can also perform simple visual inspections to keep track of their gas line condition. Checking for any signs of damage, such as dents or rust, provides an initial assessment. Additionally, monitoring the appliance performance and ensuring proper ventilation can enhance safety. If any irregularities are noted, it’s crucial to contact a licensed plumber immediately to evaluate the issue. Regular attention to gas lines can prevent costly repairs and safeguard your home.

FAQS

What should I consider before installing a gas line?

Before installing a gas line, consider factors such as the type of gas needed, local building codes, the layout of your property, and whether you need a professional installation or can handle it yourself.

How do I know if my gas line needs repair?

Signs that your gas line may need repair include a hissing sound near the line, a rotten egg smell, dead vegetation over the gas line, or higher-than-normal gas bills. If you notice any of these signs, it’s important to contact a professional immediately.

Can I install a gas line myself?

While some homeowners may have the skills to install a gas line themselves, it is generally recommended to hire a licensed professional. Gas line installation involves strict safety codes and regulations that must be followed to ensure safety.

How often should I have my gas lines inspected?

It is recommended to have your gas lines inspected at least once a year. Regular inspections can help identify potential issues before they become major problems, ensuring the safety and efficiency of your system.

What types of gas are commonly used in residential properties?

The two most common types of gas used in residential properties are natural gas and propane. Each has its own characteristics and benefits, so it’s important to choose the one that best suits your needs and location.